Free Shipping $99+ USA Only (Details)

319-364-1120

⇑ Select your sport ⇑

Polaris IQ Fine Tuning

Before fine tuning make sure you have good fuel,

good reeds, clean carbs, new

float assembly o rings, carbs in sync and your

carb pistons (aka slides) are not worn, cracked or have pieces broke off of them. This section has to do with carb tuning. Dont let any other issues like clutching, track tension, traction or wet heavy snow make you think its a carb issue.

For 440's start reading here and for 600's scroll down a bit.

440's (read below for 600's)

Fine tuning the low end on a 440 with

air screws: (stock carbs have air screws)The idle will need to be turned up on each carb. We like to set ours at 2200 RPM at about 15*f with a warm engine. Then you will need to set the air screws. Its easiest to do this with the air box off using a small screwdriver or just a screw gun bit. You want the air screw to raise the rpm and clean up the idle. Out is leaner/more air. You will usually have to turn these screws all the way in until they are lightly seated then back out as out count the turns. Make sure they are both even. Then adjust them by turning them in or out a half a turn at a time. Once you find the highest or cleanest sounding point then you will need to screw it back in about a 1/4 turn this will help the sled return to idle after running it full throttle. If it lingers up around 3 or 4000rpm for a few seconds before returning to idle this is ok and a good indication you have it set right.

We recommend our trail needles.

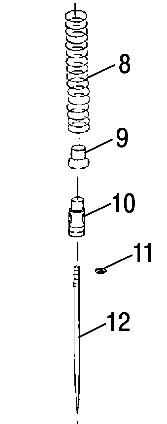

440's with oil injection: Make sure when installing the new cable that the plastic spring

guide ring (part #9 in picture below) goes all the way down over to the guide holder, aka cable holder, part #10. The spring

guide ring has a tab on the inside of it that must line up and on the guide holder just right in order for it to go down all the way. They only fit all the way down right one way. Be careful not to damage this plastic piece. If you can't pull the throttle fully open then that is most likely the problem.

Do not force it or you will break the cable junction box and improper

installation is not covered under any warranty.

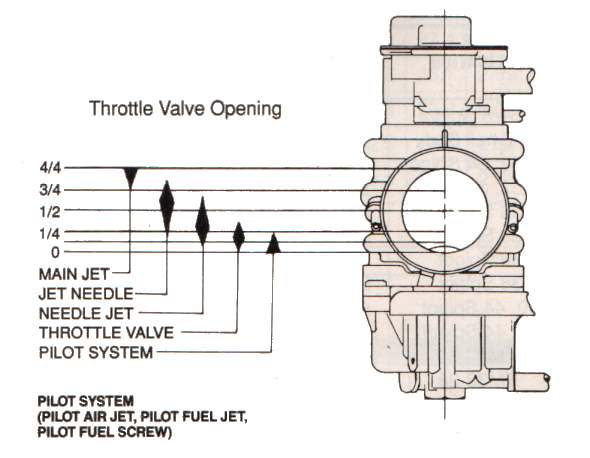

Always start from the bottom when tuning and work your way up.

600's

Fine tuning the low end on a 600 trail converted IQR with rack style carbs and

fuel screws:

(stock carbs have fuel screws and work the opposite of air screws).

We like to set our idle at 1800-2200 RPM at about 15*f with a cleaned out

and warm engine. Then you will need to set the fuel screws. Its easiest to do this with the air box off using your fingers, a small screwdriver or just a screw gun bit. You want the fuel screw to raise the rpm and clean up the idle. Remember, this is a

fuel screw so in is leaner and out is richer. You will usually have to turn these screws all the way in until they are lightly seated then back out as you count the turns. Make sure they are both even. Then adjust them by turning them in or out a half a turn at a time. Once you find the highest idle or cleanest sounding point then you will need to screw it back out about a 1/4 turn this will help the sled return to idle after running it full throttle. If it lingers up around 3 or 4000rpm for a few seconds before returning to idle this is ok and a good indication you have it set right. If you cant get it to clean out then a .8 or .9

pilot air jet (PAJ)

may be required and usually is. If you still cant get it cleaned out then

changing the pilot jet is the next step. If you wind up with a lean pilot jet

your sled will take longer to warm up on cold days-dont rush it. In some cases

we recommend raising your stock needles or using our

trail needles

(only for extreme cold weather and lots of full throttle)

if you are having a lean condition in the mid range or top end. This is common on some 600R's running in cold weather

way below 0*f.

Always start from the bottom when tuning and work your way up.