Free Shipping $99+ USA Only (Details)

319-364-1120

⇑ Select your sport ⇑

|

Polaris IQ Racer

Tuning, Modifying & Troubleshooting |

|

| Caution: Please take a few minutes to read through all of these notes. We have many hours of technical testing to come to these recommendations. If you still have questions that we have not answered on these pages and you are a current customer then please click here for tech support. | |

|

Many of the Polaris carb adaptors separate between the

rubber and the metal and/or crack out. See picture 1. They will suck

air and cause a lean condition and can blow your engine. Remove

the carbs and check yours. The ones we offer are the newest updated

ones and thicker than the stock ones. See picture 2. NOTE: For engine

serial #'s 0120327300140-0120327302497 replace both adaptors and if

your out of that serial number range don't think your ok-check your

adaptors. Carb adaptors available here |

| 440 Carb Piston valve

cutaway, 2.5 (aka carb slides) These are famous for wearing down and cracking on the engine side followed by pieces breaking off and getting sucked through you engine. Check yours and replace them if they are cracked or warn. available here |

|

|

IQ 440/600

Motor Mounts

Many of the motor mounts used after 5 years old and especially on the '05-'07 IQ 440's warp and are no longer centered up. If your having belt/clutch problems or cant get the clutches to align then check yours. available here |

| 600HO carb boots The carb boots that come on the 600RR and others that many people are using on the 600HO's in the IQ racer chassis make it very difficult to put the air box back in. We use a different set of boots that stay in the air box and slide right on the carbs. Install with the flush side out. available here |

|

|

Air box info:

600R/RR

Air box mod Make sure your air box strap is tight. You can remount the double rivet higher up on the box or go below and double up the strap under the lower air box bracket then double tie strap it. make sure your bracket is not bent back allowing the air box to rub. Next trick is to put a 1/4" rubber pad underneath the gas tank in the front to help space it up a little and allow the air box to be removed and installed easier. Put your hand in the box and lift up on the carbs while installing. |

|

Additional info on Reeds: Many people doing 440 to 600 conversions are removing the 440 V-Force reeds and putting them in the 600's. This is ok however your should use the proper stuffer. Example of the larger 600 stuffer up against the 440 stuffer in the (top picture). The proper 3 petal reed valves from V-Force are here and come with the 100 thousands spacer kit. Although rare, some may also need to do a case mod (bottom picture) if you are running out of fuel at full throttle because the fuel pump cant pump enough. This helps the pulse line fitting by grinding out a groove into the case. This modification should only be performed by a professional. |

|

Team secondary spacer/washer part # 11. If yours is grooved its time for a new one. We also recommend the Delrin washers for your secondary spring. Available here |

|

Delrin Washers Eliminates friction and spring fatigue in Team secondary clutches. Available here |

|

Primary spring break? Many the new Polaris clutches have sharp edges on the jam nuts that are not tapered that will need to be carefully ground down with a Dremel or air grinder. Remember, this is a balance unit so you need to remove the same amount from all sides. If you have the tools and access to a lathe you can taper it but you will still need to remove any sharp edges. This will prevent the primary springs from being scored/scratched until they break. Many of the manufactures will warranty the first broken spring if you call them. |

|

Skis, For trail riding I recommend the stock Polaris

snow cross ski, IQ2 or Pro-Steer. The stock snox ski has a full length carbide that is the same one

Polaris has used for 12 years now so they are easy to find. Many of the

C&A skis push snow on the keel and the start of the carbide. On

certain skis this can toss you all over the place while your riding

them. The wider Skis seem to be worse. Remember, the snow cross guys

are usually in deep artificial snow and need the lift.

Skis available here. |

New  New  Worn  Worn |

Why oil

inject your IQR for trail riding?

Your engine will last twice as long with oil injection as long as it

is an option 2 or 3 from JS Powersports or any for engines that have

check valves already in the case. Even the Polaris race dept

recommends it on all cross country (xc) and distance racing sleds.

They got the original info from JS Powersports to use and have been

running/recommending it ever since. In normal racing as this sled was

designed for there are usually short bursts of throttle an on the

track for less than

15 minutes at a time and then the engines are overhauled at least once

a year. If your blazing down the trail and holding constant then you

are stressing the engine for longer that it was intended to use to.

Sure they are strong engines but you should protect them if you want

them to last. Now the newer sleds, '15 and up, even come with the

check valves in the block for easy set up. First 2 pictures are of a

good worming gear and cross shaft. Last 2 are of warn ones that have

about 3-4k miles on them without oil injection. Normally an engine

with oil injection will go 8-10k miles before they look like that.

Only reason I have ever seen an oil injection pump fail after 25+

years of wrenching professionally is if you run it out of oil.

I can explain how the premix barely lubes the cross shaft through a

small hole at the top of the case and the small off center slot at the

bottom or you can just imagine oil injection dripping directly on it

making it last longer. Kits can be ordered here:

Link to the original oil Injection

kits from us. Why you should buy the original oil injection kit from us- video: https://www.youtube.com/watch?v=oPEEAzYH5EE&t=1s |

| Oil injection pumps Recently we have seen and heard of a few sleds that were leaking 2 cycle oil on the ground while in storage. I strongly recommend everyone checking the air bleeder screw on the end of the oil injection pump on the right hand side. The last 2 brand new ones we got in from Polaris to install were lose. We do not recommend plugging any of the oil injection lines. The pump can and usually will blow the plug off and leak oil. We are hearing of to many guys using a screw or bolt to plug the extra oil line and the oil will still get pushed through the threads and leak. We actually recommend putting a T fitting in the line instead of a plug. While your at it check to make sure the index marks are set correctly. Adjust the cable if necessary. Also, while were talking about 2 cycle oil leaks there are also some people who are not running a gasket under the oil tank cap that is causing leaks and a few others that have not run a vent tube properly or one at all on the oil tank. We recommend running a vent tube down the steering loop bar on the right hand rear side until it goes below the oil tank a few inches and then putting in a easy bend and running it back up slightly past the top of the oil tank and then turning the tube in a downward position before attaching with zip ties, just snug. Be sure you don't kink the line or over tighten the zip ties. This will allow the vent to work but yet not leak out too much oil when the sled is on its side or upside down if that were to happen. Oil isn't cheap so have a look and correct if necessary. |

|

|

Track to tight and the adjusters all the way out? click here |

|

Bogie wheel bolt touching shock reservoir? click here |

|

Engine sluggish or running hot? Supplement Rear Heat Exchanger can be found on this page |

|

Fuel tank hard to reinstall-expanded?

click here Fuel leaking click here Trail Tank |

| Electrical issues causing sled to not run right? click here | |

|

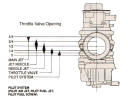

Troubleshooting Sled wont pull full RPM's? Check your carbs first then reeds, power valves and clutches. You defiantly have a problem if your not turning full RPM or close to it. Chasing the last 200 RPM's may be a waste of time if the sled is running good because many of the tachs are off by up to 200 RPM's. What your looking for is dirty carbs, plugged jets including the PAJ, bad carb adaptors, broken reeds, stuck power valves or ripped diaphragms, or a stuck choke (should be able to slide a penny under the choke lever), and on the clutches, make sure the weight bushings are tight and not rubbing the spider as they move outward. Check the rollers. Check for broken springs and broken rollers in the secondary too. Important, Most of these sleds after three or four years the fuel pickup line inside of the fuel tank will dry rot and go bad. If the line is good it should still be purple if it looks like a yellow or brown it is bad and will eventually break . If this has ever happened then there is a very good chance that chunks of plastic and chunks of hose have been sucked through the system and could be anywhere in the inlet system which means they could be plugged up in the 90 degree fitting coming out of the fuel tank or plugged up in your fuel pump or could have damaged the diaphragms on the fuel pump or they could have made it through there and wound up either in the T section between the two carburetors or right on top of a needle and seat not allowing it to shut off when it should . If the fuel line has been broken in the tank be sure to go through all of those things and pull out the float assembly carefully and blow out those lines with an air hose or physically inspect all of it to make sure it is clear . The other things that we commonly see are Pilot Air Jets that are plugged and go in the very back of the carburetor next to the air box . We also see a lot of stretched choke cables that are pulling up on the plunger inside the carbs or just dirty carbs where the plunger stick and do not seal off causing the sled to get excess fuel . All these things will make your engine run bad. If you punch the throttle at idle and the sled just dies or if you have to lightly apply the throttle and ease into it to get it to run up to speed then you are dealing with a lean condition normally considered a bog. A blog will normally sound like a sick cow and somewhat low pitched And if you keep riding with the lean condition that's where engines normally will blow up. On the other hand if you are hammering the throttle and the sled has to clear out and then finally go and runs better at top end then you most likely have a rich condition which could be from the things we talked about before where the chokes are stuck or sticking open or there's debris above the needle and seat which is incorporated in the float assembly on most of these machines allowing too much fuel to go through or the float assembly O rings themselves have dried and cracked or are smashed and leaking past normally due to the ethanol in all of the fuels. Don't think for a second you're getting fuel without ethanol in it. If your sled seems to be cutting out and feels like it might be electrical then unplug everything on the handlebars and the hood and see if it returns to normal. It does start plugging things back in one at a time until you find the problem. On the older sleds it is common for the high beam low beam switch to go bad and for that wire to touch the handlebars which is grounded and can cause the machine to shut off. These older machines are also famous for having bad voltage regulators which can cause all kinds of electrical issues. If the sled has ever been rolled over there's a chance that a heater element otherwise known as your handlebar heater has been cut and is grounding out to the handlebars. Many of these sleds also have a heater element attached to the tunnel underneath the tank or other places underneath the hood to bleed off excess ac current to help the voltage regulator so it doesn't burnout so fast . If one of these has rubbed through in his touching ground it will also cause a cutting out problem. More: Electrical issues causing sled to not run right? click here |

|

|

Fine tuning the low end click here |

| Leaking Fuel?

Video here Needle and seat o rings may be bad. Purchase here |

|

No brapp brapp? |

Fuel delivery and Spark testing, troubleshooting |

|

|

|

|

|

|